HEAT TREATMENT SERVICES

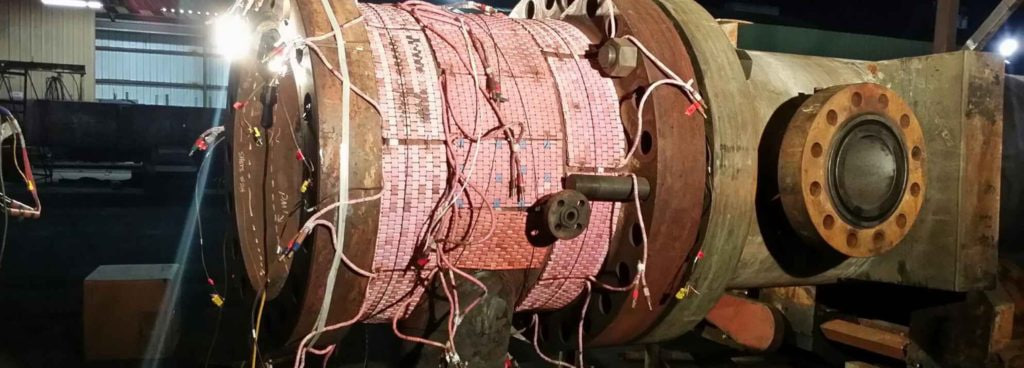

Alliance Infinite offers Heat treatment services such as stress relieving, normalizing, solution annealing, hydrogen diffusion, intermediate stress relieving, tempering etc. Alliance Infinite provides post weld heat treatment by using electricity as source of heating for stress relieving of weld joints as well as also uses diesel fuel as source of heating for stress relieving for pressure vessels. Our heat treatment services are designed to minimize downtime, improve structural integrity, and enhance effective plant life. Additionally, depending on the mobility of the required equipment many of our heating processes can be applied on-site or at your facility.

Post weld heat treatment reduces the residual stresses formed during welding. It also restores the macro structures of the steel. PWHT requirements are to be strictly followed in high pressure applications to avoid component failure.

PWHT eliminates the effects by heating , soaking & cooling the weld area in controlled manner to temperature below the first transformation point , giving the macro structure sufficient time to readjust to its original state & removing the residual stress.

Heat treatment process is carried out by using following methods

- Electrical Resistance Heating Method

- Internal Heating Method using Gas / Oil Fired High Velocity Burner.

- Temporary Gas / Oil / Electrical Fired Furnace.

Product Range

- Furnace Equipment

- Heat Treatment Equipment – Mobile

- Temporary Gas / Oil / Electrical Fired Furnace.

All PWHT equipments are well maintained & have a valid current calibration certificate. Electric power sources are 380/440V 3 phase 50Hz primary supply step down transformer secondary output (heat treatment unit) giving low voltage circuits. Temperature control equipment is either manually operated through energy regulators or automatically operated using modular controls. Recording of temperature, for the electrical resistance method, or the induction heating method is by means of calibrated chart type temperature recorder. Calibration frequency of recorders will be one year